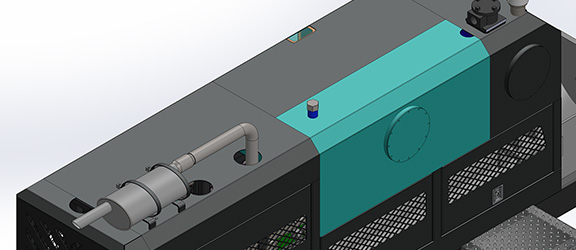

Developed by EVOMAQ® to optimize the logistics of foundation, earthmoving, and concrete companies, increasing productivity on construction sites. This compact-sized equipment can be transported together with a drilling rig on the same truck, offering easy operation in small or hard-to-reach areas.

Keeping the equipment clean is the first step to ensuring good performance and long service life. That’s why the EVOMAQ® concrete pump water tank features a powerful pressurization system, making cleaning and maintenance much easier.

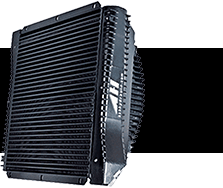

An efficient cooling system stabilizes the oil temperature, maintaining proper viscosity and preventing premature wear of the hydraulic system.

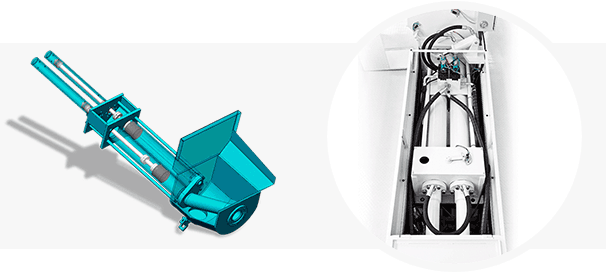

The rounded hopper design simplifies cleaning and helps direct concrete more efficiently into the delivery cylinders, increasing pumping performance.

The hopper cleaning valve also stands out with its exclusive lever system, allowing it to be opened from the side of the machine, making cleaning and maintenance even easier.

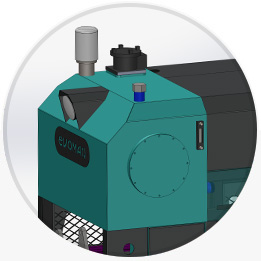

All EVOMAQ® equipment comes equipped with a powerful hydraulic mixer, ensuring that the concrete remains properly mixed between loads.

The optimized pumping system reduces the number of components, resulting in greater productivity and lower maintenance costs.

An efficient cooler system stabilizes oil temperature, keeping it properly viscous and preventing early hydraulic wear.

The EVOMAQ® pump’s electrical system stands out for its simple design, making operation easier and eliminating relays and timers by using a limit switch instead — once again resulting in lower maintenance costs.

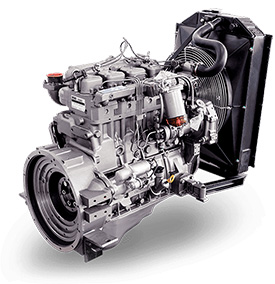

The hydraulic pump can also be powered by a robust MWM auxiliary engine, engineered to deliver power and performance.

| Models | AL 1560 | AL 1570 Piston Side | AL 1570 Rod Side |

|---|---|---|---|

| Maximum Theoretical Output (m³/h) | 51 | 50 | 85 |

| Cycles per Minute | 24 | 19 | 32 |

| Cylinder Diameter (mm) | 90/63 | 110/63 | 110/63 |

| Maximum Aggregate Size (mm) | 25 | 25 | 25 |

| Cylinder Stroke (mm) | 1400 | 1400 | 1400 |

| Delivery Cylinder Diameter (mm) | 180 | 200 | 200 |

| Engine Power (hp) | 152 | 215 | 215 |

| MWM Engine Model | 4.12TCA | 6.10TCA | 6.10TCA |

| Concrete Volume per Stroke (liters) | 35,62 | 43,98 | 43,98 |

| Type of Diverter Tube | "S" | "S" | "S" |

| Horizontal Pumping Distance (m) | 350 | 500 | 350 |

| Vertical Pumping Distance (m) | 100 | 120 | 80 |

| Weight with Auxiliary Engine (kg) | 4.200 | 6.000 | 6.000 |

This website uses cookies and similar technologies and by continuing to browse you agree to the terms of our Privacy Policy.

X