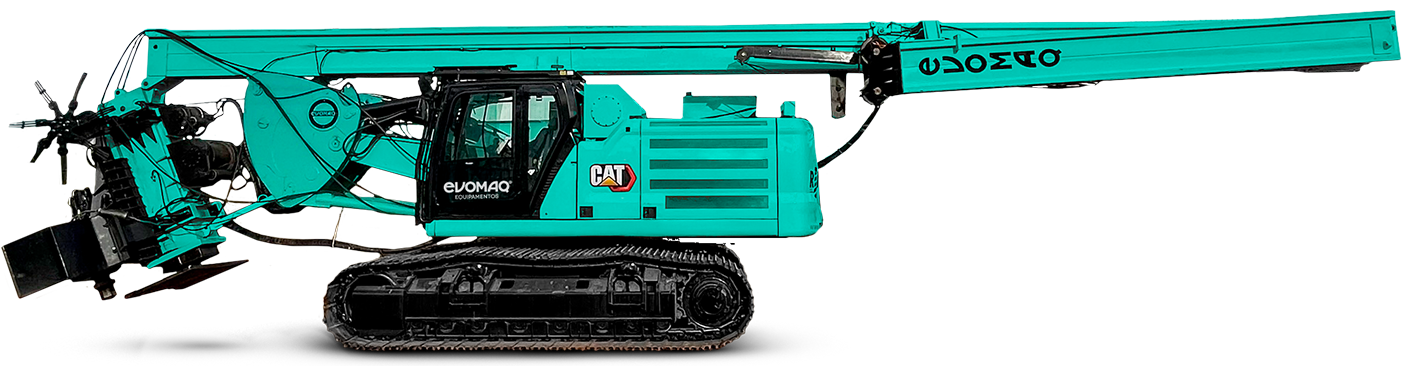

The EVOMAQ® E1200/31 drill rig comes equipped with a TOP DRIVE drilling head, capable of drilling diameters up to 1,200 mm and reaching depths of 31 meters. Mounted on an excavator chassis, it delivers a maximum torque of 32,000 kgf.m, with a 360° rotation system designed to maximize usability, productivity, and safety.

This high-performance rig is built for large-scale projects, combining advanced technology, multiple functionalities, and superior efficiency.

This system allows the machine, once disassembled, to reach the dimensions required for transport.

However, the main advantages of the pantograph are evident during operation. It optimizes time on the job site, while providing greater mobility and safety. With this tower forward-and-reverse mechanism, the operator can drill piles near slope edges without repositioning the entire machine, minimizing the risk of soil collapse.

The operator can position the machine farther from the slope and extend only the tower toward the drilling point. Another key advantage is the ability to drill multiple piles without needing to move the tracks.

In addition, the rig’s 360° rotation enhances pantograph use even further. The combination of these two systems provides excellent operational range and versatility, allowing access to piles positioned all around the machine.

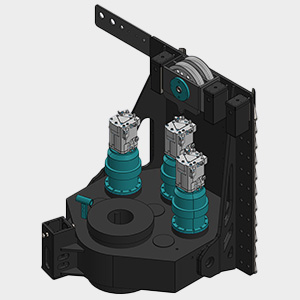

To match the robustness of this equipment, we developed a high‑performance hydraulic assembly capable of delivering an impressive 32,000 kgf.m of force, ensuring superior performance even in the most demanding operations. The drilling head maintains its original design, but in this version it has received important structural reinforcements. The Linde hydraulic motors—larger than those used in previous versions—are coupled to four powerful Brevini reducers.

This combination, together with the high power of the diesel engine and a carefully engineered hydraulic system, allows the equipment to reach 32,000 kgf.m of torque, resulting in significantly above‑average productivity when compared to competing machines.

To support a rig as robust as this one, EVOMAQ® designed a high-performance hydraulic system capable of delivering an outstanding 32,000 kgf.m of raw torque, power, and performance.

Our drilling head remains compact, but for this equipment version, it has been significantly reinforced! In this model, the larger Linde hydraulic motors, compared to previous versions, are coupled with three powerful Brevini reducers. Together with the high-output diesel engine and a precisely engineered hydraulic system, this configuration enables the rig to reach an impressive torque of 32,000 kgf.m.

EVOMAQ® has implemented advanced design techniques and features that allow 360° rotation, maximizing usability, productivity, and operator safety.

To maintain auger alignment during drilling, the EVOMAQ® rig features a universal hydraulic clamp system compatible with all auger diameters, providing greater operational safety and convenience for the operators.

The EVOMAQ® Continuous Flight Auger Drill is equipped with a high-tech monitoring computer that provides accurate, real-time data on drilling and concreting processes through detailed graphs, ensuring greater reliability for the operator.

This rig operates with a minimum drilling diameter of 300 mm and a maximum of 1,200 mm, covering a range suitable for various ground conditions and project requirements. This flexibility ensures optimal performance and adaptability for different applications.

To achieve the 31-meter drilling depth, EVOMAQ® designed larger, stronger, and more stable tracks, ensuring maximum safety and balance during operations. The system also includes a hydraulic track-widening mechanism, allowing an expansion of up to 800 mm, which further enhances stability and maneuverability on the job site.

In addition to providing greater agility, the hydraulic mast adjustments are essential for the safe movement of the machine on the job site. While in motion, the mast can be tilted sideways or backward, maintaining the center of gravity and ensuring even greater operational safety.

EVOMAQ® offers customers the option to choose between Caterpillar and Komatsu excavator chassis. For other chassis manufacturers, custom project development may be required.

| Specifications | CFA Drilling Rig P70/20 | CFA Drilling Rig E70/20 | CFA Drilling Rig E70/22 | CFA Drilling Rig E80/25 | CFA Drilling Rig P1100/28 | CFA Drilling Rig E1000/31 | CFA Drilling Rig E1200/31 |

|---|---|---|---|---|---|---|---|

| Minimum Drilling Diameter | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm |

| Maximum Drilling Diameter | 700 mm | 700 mm | 700 mm | 800 mm | 1.100 mm | 1.000 mm | 1.200 mm |

| Maximum Drilling Depth | 20 m (14+6) | 20 m (14+6) | 22 m (16+6) | 25 m (19+6) | 28 m (22+6) | 31 m (24+7) | 31 m (24+7) |

| Maximum Torque | 10.000 kgf.m | 10.000 kgf.m | 13.000 kgf.m | 18.000 kgf.m | 22.000 kgf.m | 22.000 kgf.m | 32.000 kgf.m |

| 1st Gear Rotation | 9 RPM | 9 RPM | 14 RPM | 14 RPM | 14 RPM | 14 RPM | 14 RPM |

| 2nd Gear Rotation | 14 RPM | 14 RPM | 22 RPM | 19 RPM | 20 RPM | 20 RPM | 20 RPM |

| 3nd Gear Rotation | 20 RPM | 20 RPM | 27 RPM | 24 RPM | 28 RPM | 28 RPM | 26 RPM |

| 4th Gear Rotation | 29 RPM | 29 RPM | 32 RPM | 33 RPM | 34 RPM | 34 RPM | 35 RPM |

| Extraction Force | 45.000 kgf | 45.000 kgf | 64.000 kgf | 64.000 kgf | 64.000 kgf | 116.000 kgf | 116.000 kgf |

| Engine Power | 330 cv |

* * |

140 hp * |

* * |

360 cv |

* * |

* * |

| Inclination | 5,03° | 3° | 3° |

* * |

3,5° | 3° | 3° |

| Transport Weight | 21.000 kg |

* * |

27.000 kg | 44.000 kg | 52.270 kg |

* * |

* * |

| Track Length | 4.450 mm | 4.240 mm | 4.000 mm | 4.500 mm | 5.000 mm | 6.000 mm | 6.000 mm |

| Track Width | 600 mm | 700 mm | 700 mm | 800 mm | 750 mm | 800 mm | 800 mm |

| Length (Working) | 5.811 mm | 5.875 mm | 6.340 mm | 7.030 mm | 8.311 mm | 11.000 mm | 11.000 mm |

| Length (Transport) | 9.500 mm | 9.377 mm | 10.926 mm | 16.031 mm | 18.217 mm | 20.675 mm | 20.675 mm |

| Width (Working) | 3.722 mm | 2.690 mm | 2.798 mm | 4.370 mm | 4.380 mm | 4.370 mm | 4.370 mm |

| Width (Transport) | 2.530 mm | 2.690 mm | 2.798 mm | 3.170 mm | 3.180 mm | 3.170 mm | 3.170 mm |

| Height (Working) | 23.047 mm | 23.192 mm | 26.026 mm | 29.420 mm | 32.553 mm | 35.110 mm | 35.110 mm |

| Height (Transport) | 2.750 mm | 2.990 mm | 2.984 mm | 3.584 mm | 3.632 mm | 3.600 mm | 3.600 mm |

| Effective Stroke of the Pantograph | 1.200 mm | 1.300 mm | 1.300 mm |

* In this model, the customer can select their preferred chassis brand: Caterpillar or Komatsu. For other chassis manufacturers, please check availability with the engineering department.

This website uses cookies and similar technologies and by continuing to browse you agree to the terms of our Privacy Policy.

X